Recent Work

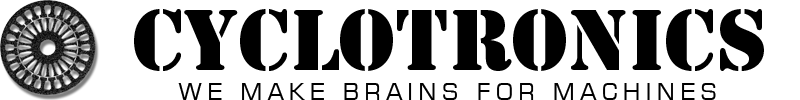

Brushless DC Servo Amplifier

The customer required an off-line driver for an 80 volt BLDC servo motor. The customer also needed 12 volts DC to power the rest of their application. Recognizing that these two functions could share a common PFC front-end, Cyclotronics delivered an efficient single PCBA serving both requirements. Although the customer chose a six-step commutated motor for cost reasons, the design is capable of sinusoudal commutation.

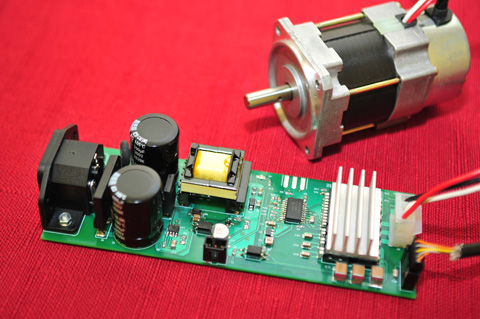

Beverage dispenser

Our customer was building an on-demand beverage mixing and dispensing system. The control was a PLC with a separate touch screen. The application needed to control 18 solenoid valves, a heater, temperature sensors, level sensors, and support user interaction via a touch screen.

Our customer was building an on-demand beverage mixing and dispensing system. The control was a PLC with a separate touch screen. The application needed to control 18 solenoid valves, a heater, temperature sensors, level sensors, and support user interaction via a touch screen.Cyclotronics replaced the PLC, touch screen, signal conditioning modules, and power supply with a single assembly incorporating all functions and directly driving a color TFT touch screen. By using a connectorized harness instead of discrete wiring to terminal blocks, assembly time and rework was dramatically reduced. Not counting labor savings, the Cyclotronics solution reduced the cost of electronics by 35%.

Another concern of this customer was frequent software updates. With the PLC, these required the field service technician to carry a laptop and use specialized software. Firmware for the Cyclotronics solution is updated by a simply pliugging a thumb drive into the machine. The controller recognizes the drive and re-flashes itself without the need for an external computer. The technician then removes the thumb drive and carries it to the next site.

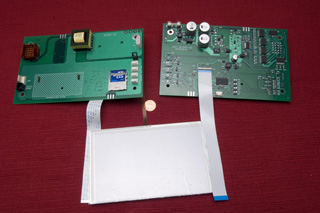

High Reliability

This aerospace application was required to have a ten-year shelf life with extreme variations in temperature and then to start up and operate in milliseconds. The existing design often failed. Cyclotronics' re-design eliminated all electrolytic capacitors, which have poor shelf life, and a mechanical relay.

This aerospace application was required to have a ten-year shelf life with extreme variations in temperature and then to start up and operate in milliseconds. The existing design often failed. Cyclotronics' re-design eliminated all electrolytic capacitors, which have poor shelf life, and a mechanical relay. Besides fixing the shelf life problem, the new design delivered enhanced performance and more reliable operation and its higher efficiency reduced the size of battery pack required by 33%.

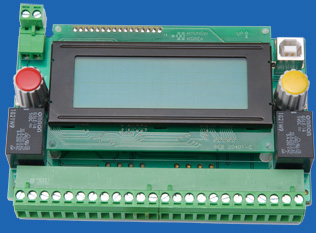

Water treatment system

The customer has invented an entirely new water treatment process. The control system needs to regulate the concentration of a solution and balance flow rates into and out of the reaction. Because the process is new, the customer wishes to collect data but the machine is located at a remote site.

The customer has invented an entirely new water treatment process. The control system needs to regulate the concentration of a solution and balance flow rates into and out of the reaction. Because the process is new, the customer wishes to collect data but the machine is located at a remote site.Cyclotronics provided a custom controller with all functions except for two large contactors on a single printed circuit board. Process parameters can be adjusted using a pair of digital knob encoders and a B&W LCD display. Data is logged to an SD card which the customer can remove at service intervals and carry back to the city for download and evaluation.

The process is regulated by a custom servo algorithm designed from the customer's specifications for reaction stoichiometry. This algorithm is integrated as a function block accessible to the main ladder-diagram program.

Solar charging system

A major automaker wished to deploy solar charging stations for electric vehicles. The system integrator for the solar power system implemented a PLC system but there was no off-the-shelf means to interconnect the control system to the vehicle's communication bus.

A major automaker wished to deploy solar charging stations for electric vehicles. The system integrator for the solar power system implemented a PLC system but there was no off-the-shelf means to interconnect the control system to the vehicle's communication bus.

Cyclotronics provided a custom translator which communicates with the vehicle electronics and makes parameters and status information accessible to the PLC as Modbus registers.

We believe this project would not have been completed on time, if at all, without Cyclotronics' small contribution.

Industrial process

The manufacturer of equipment for an electro-chemical process was using PLC controls in conjuction with a large custom power supply. They wished to expand their customer base by offering smaller scale models but the cost of the control system did not scale down with the rest of the system.

The manufacturer of equipment for an electro-chemical process was using PLC controls in conjuction with a large custom power supply. They wished to expand their customer base by offering smaller scale models but the cost of the control system did not scale down with the rest of the system.

An additional problem was the ease with which competitors could reverse-engineer the PLC-based control system.

Cyclotronics intergrated the control logic into the power supply, reducing the system cost and making it impossible for competitors to retrieve the control program. A bonus advantage is that the physical footprint of the controls cabinet was reduced.

Solar Powered Lighting

Our customer manufacturers and installs solar-powered outdoor lighting. Their system architecture used three different components: a charge controller, a photocell/timer, and an LED driver. All were from different Chinese vendors and involved different configuration paradigms.

Our customer manufacturers and installs solar-powered outdoor lighting. Their system architecture used three different components: a charge controller, a photocell/timer, and an LED driver. All were from different Chinese vendors and involved different configuration paradigms.

Cyclotronics designed a single module incorporating all three functions. The module is sealed to IP67. Configuration is via a single USB port and a small custom Windows program. Besides simplifying installation and configuration, the Cyclotronics solution offers increased functional flexibility. The higher efficiency of the Cyclotronics electronics, 96% compared to 88% for the legacy solution, allows the system to tolerate more cloudy days in a row.

Because the Cyclotronics module is made in the USA, the customer was able to increase the US content of their product enough to qualify for new GSA contracts.

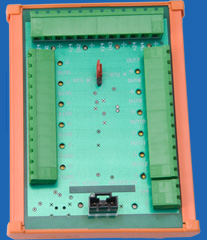

Remote I/O

A control system included a large number of connections to a remote vavle cabinet. Due to the diversity of I/O types, an off-the-shelf RTU would have been prohibitively expensive. Cyclotronics designed a custom remote terminal unit incorporating outputs for two valve types and inputs for level and pressure sensors into a single DIN-rail module. Discrete wiring was replaced with Category-5 cable and inexpensive industrial Ethernet connectors.

A control system included a large number of connections to a remote vavle cabinet. Due to the diversity of I/O types, an off-the-shelf RTU would have been prohibitively expensive. Cyclotronics designed a custom remote terminal unit incorporating outputs for two valve types and inputs for level and pressure sensors into a single DIN-rail module. Discrete wiring was replaced with Category-5 cable and inexpensive industrial Ethernet connectors.

The new cabling system and the RTU together cost less than just the multipole connectors previously used. Besides lowering BOM cost, installation labor and the potential for wiring errors were both dramatically reduced.